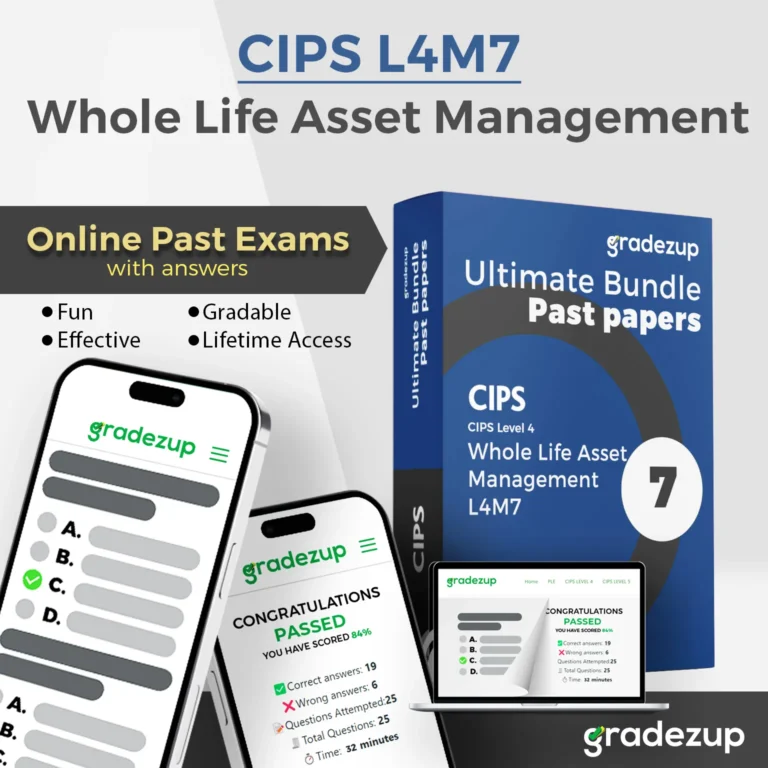

Ready to excel in your CIPS L4M7 Exams

Time's up

Time is Up!

Access more CIPS L4M7 Exam Past Papers

Access more CIPS L4M7 Exam Past Papers

✨ Premium Access ✨

Note: $4.99 grants you access to all papers (paper 1 – paper 7)

Gain access using

Practice Gradezup Pass L4M7 Exams

L4M7 Past Exams

Fix access error

Are you having trouble accessing papers after purchase. No worries just submit you account email to reboot the access instantly.

L4M7 Quick Exam-Ready Summary:

- Core Module

- Objective / Response Exam

- 1.5 hours Exam duration

- 60 Questions in exam

- 6 Credits Score

Inventory Storage & Movement

Warehouse design, product coding (RFID, barcode), automation, equipment types

Inventory Control

Inventory classification, cost categories, forecasting, control systems (MRP, JIT, ERP), KPIs

Whole-Life Costing

TCO components, cost model construction, hidden costs, disposal, legal & environmental factors

CIPS L4M7 Focus Areas – 2025 (Master List)

“These are core learning areas, but CIPS may include questions from other parts of the syllabus.” ⚠️

1. Methods for Storage and Movement of Inventory

- Store & Warehouse Design:

- Optimal location, layout, and design considerations

- Importance of flow, spatial efficiency, and flexibility

- Product Coding & Tracking Systems:

- Types: barcode, QR code, RFID

- Applications in order tracking and identification

- Warehouse Equipment & Automation:

- Materials handling equipment (e.g. conveyors, forklifts)

- Pallets, unit loads, containerisation, packaging standards

- Automation technologies in warehousing

2. Key Elements of Effective Inventory Control

- Inventory Classifications:

- Types include opening stock, raw materials, work in progress, safety stock, finished goods, obsolete/redundant items

- ABC stock classification and dependent vs. independent demand items

- Costs of Holding Inventory:

- Acquisition, holding, and stock-out costs

- Strategies to reduce costs without compromising service levels

- Inventory Control Techniques:

- Forecasting: subjective vs. objective

- Reorder quantities and levels

- Use of MRP/MRP II, ERP, just-in-time (JIT), lean methods

- Performance metrics: lead times, stock turns, service levels, stock cover, stock-outs

3. Whole-Life Costing Concept

- Total Cost of Ownership (TCO) Components:

- Cost drivers: purchase price, hire/lease, acquisition, usage (maintenance, operation, utilities, training), disposal/end-of-life costs

- Building a Whole-Life Cost Model:

- Guidelines: include all cost elements, use best available data, account for hidden costs (e.g., extended supply chain risks)

- Apply only for significant purchases, with senior management and cross-functional support, and team collaboration to expedite data collection

- End-of-Life Cost Factors:

- Decommissioning, removal, disposal (including closed-loop recycling), legal and environmental considerations

- Align with triple bottom line approach: people, planet, profit CIPS Official

View more CIPS Exams

Select the Exams you want to practice