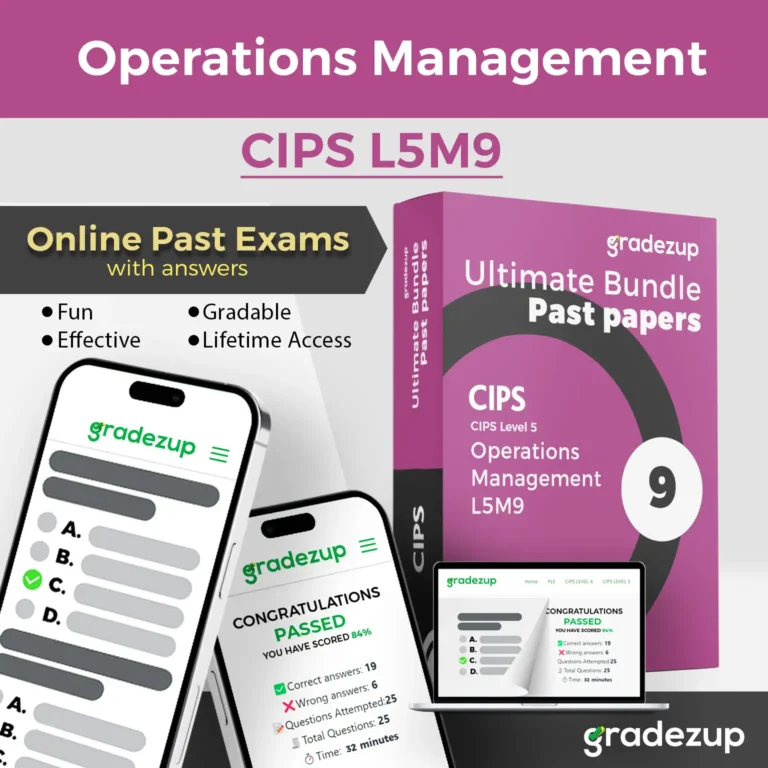

Ready to excel in your CIPS L5M9 Exams

Time's up

✨ Premium Access ✨

Access more CIPS L5M9 Exam Past Papers

Access more CIPS L5M9 Exam Past Papers

Note: $4.99 grants you access to all papers (paper 1 – paper 10)

Gain access using

Practice Gradezup Pass L5M9 Exams

L4M5 Quick Exam-Ready Summary:

- Core Module

- Objective / Response Exam

- 1.5 hours Exam duration

- 60 Questions in exam

- 6 Credits Score

Principles of Risk Management

Definitions, frameworks (ISO 31000, COSO), resilience, governance, risk appetite, global drivers

Risk Identification & Classification

nternal vs external risks, PESTLE/STEEPLED, Porter’s Five Forces, demand, logistics, financial, ESG risks

Risk Assessment & Analysis

Heat maps, probability–impact matrices, risk registers, Monte Carlo, FMEA, supply chain mapping

Mitigation & Management Strategies

Strategies Avoid, transfer, reduce, accept; redundancy, diversification, collaboration, contracts, BCP, DRP

Monitoring & Continuous Improvement

KRIs, dashboards, blockchain, continuous review, lessons learned, reporting, governance integration

CIPS L5M2 Exam Focus Areas – 2025 (Master List)

“These are core learning areas, but CIPS may include questions from other parts of the syllabus.” ⚠️

1. Principles of Risk Management in Supply Chains

- Key Concepts of Risk:

- Definitions: risk, risk management, uncertainty, resilience, robustness

- Categories of risk: pure vs speculative; known vs unknown vs unknown-unknown

- Differences between enterprise risk management and supply chain risk management

- Risk appetite and tolerance within organisations

- Importance of risk culture and governance structures

- Frameworks and Approaches:

- ISO 31000, COSO, and other formal frameworks for risk management

- Supply chain risk maturity models (basic → advanced proactive systems)

- Role of supply chain visibility in enabling effective risk management

- Drivers of Risk in Modern Supply Chains:

- Globalisation and extended supply chains

- Outsourcing and offshoring

- Just-in-Time and lean practices (reducing buffers, increasing exposure)

- Political, environmental, and economic volatility

2. Risk Identification and Classification

- Internal vs External Risks:

- Internal: operational errors, process breakdowns, supplier failure, capacity shortfalls

- External: natural disasters, geopolitical instability, pandemics, cybercrime, regulatory changes

- Risk Categorisation Frameworks:

- PESTLE / STEEPLED (political, economic, social, technological, environmental, ethical, legal, demographic)

- Porter’s Five Forces (impact of buyer/supplier power, competitive intensity, substitutes, new entrants)

- Supply market mapping and segmentation

- Risk Sources in Supply Chains:

- Procurement and sourcing risks

- Logistics and transportation disruptions

- Demand volatility and forecasting errors

- Financial and currency risks

- ESG (Environmental, Social, Governance) and reputational risks

3. Risk Assessment and Analysis

- Assessment Tools:

- Risk registers and heat maps (likelihood vs impact grids)

- Probability–impact matrices

- Risk scoring and prioritisation methods

- Analytical Techniques:

- Qualitative vs quantitative assessment

- Monte Carlo simulation and sensitivity analysis

- Failure Mode and Effects Analysis (FMEA)

- Supply chain mapping to highlight critical nodes

- Prioritisation of Risks:

- Identifying high-impact, high-likelihood events

- Considering low-likelihood, high-impact “black swan” risks

- Developing critical supplier risk profiles

4. Mitigation and Management Strategies

- Strategic Options (the 4Ts):

- Avoid → eliminate risky activities/suppliers

- Transfer → insurance, contractual clauses, outsourcing

- Reduce → process controls, dual sourcing, supplier audits

- Accept → live with tolerable risks

- Tactics in Supply Chain Context:

- Redundancy (extra capacity, safety stock, alternative suppliers)

- Diversification (multi-sourcing, multi-location)

- Collaboration with suppliers for joint risk management

- Contractual protection: indemnities, force majeure, liquidated damages

- Financial instruments and insurance policies

- Business Continuity & Resilience:

- BCP (Business Continuity Planning)

- DRP (Disaster Recovery Planning)

- Crisis management planning and communication strategies

5. Monitoring, Reporting, and Continuous Improvement

- Ongoing Risk Monitoring:

- Key Risk Indicators (KRIs) and dashboards

- Early warning systems, predictive analytics, and IoT monitoring

- Blockchain for secure risk tracking

- Review and Learning:

- Periodic reviews of risk registers and mitigation strategies

- Lessons learned from major disruptions (COVID-19, Brexit, natural disasters)

- Continuous improvement tools: Kaizen, Six Sigma, Lean links

- Governance and Reporting:

- Risk reporting to senior management and boards

- Integration of supply chain risk into ESG reporting and compliance obligations

- Communication with stakeholders and regulatory bodies

View more CIPS Exams

Select the Exams you want to practice